“The author, for thirty years, has concerned himself in a process that had an indifferent beginning, a somewhat unfortunate history, and yet a process of singularly technical brilliance – in some directions not sufficiently appreciated. This is a process that can produce work of inimitable artistry and of great delicacy, a process capable of lengthening the life of a critical machine part by many hundreds of times, and a method that can transform and shape an aircraft section more easily and effectively than by any other means.

This same process carries out the mundane job of removing moulding sand from iron and steel castings, and cleans and prepares many other metals and materials with an effectiveness incomparable with any other means. The process was originally known as sandblasting.”

That was not written by me. Although I wish it had been. What a great introduction to this fascinating process. That was written by H J Plaster in 1972. It is the introduction to his book Blast Cleaning and Allied Processes. If you want to know the history and fundamentals of the blast cleaning process, this book is a great place to start (if you can get your hands on a copy). Seems he also wrote something, in 1946, called German Metal Spraying Techniques for the British Intelligence Objectives Sub Committee. Sounds interesting, but not of our concern.

Today the process of sand blasting is more commonly referred to as “abrasive blasting”. Or, when tighter specificity is required, shot blasting, grit blasting, shot peening, wet blasting, ice blasting, plastic media blasting and a multitude of other more descriptive terminologies.

Regardless of the terminology used, the process, that of impacting a surface with lots of tiny high speed particles, remains fundamentally the same. And has done since first invented. The process is widely acknowledged to have been created by Benjamin Chew Tilghman in 1871.

portrait of BC Tilghman

portrait of BC Tilghman

Reportedly, as a General in the US Army during the Civil War, B C Tilghman was garrisoned in the wild west desert. It was here that he noticed the effect of wind blown sand on the army huts glass windows. Areas of glass covered with wire mesh or bars remained clear. Whilst areas uncovered, were unprotected from the wind blown sand, and became frosted.

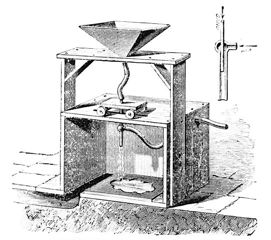

And so, with that observation, Mr Tilghman dodging arrows and peering through frosted glass, began an extraordinary industry. After his army days, and being somewhat of an entrepreneur, he went on to invent an apparatus to project sand particles at high speed using compressed air. He held many patents, carried out much detailed research on the process and did a lot of the ground work to push forward the industry.

early sand blasting apparatus patented by BC Tilghman

early sand blasting apparatus patented by BC Tilghman

Of course the process has been actually been present in nature for millennia. Those ancient Egyptian stone pyramids and sphinx were once in pristine condition. Until thousands of years of wind and sand erosion got the better of them.

Today abrasive blasting is a huge, mostly hidden, industry worth hundreds of millions of dollars annually. Every person on the planet is, unknowingly, touched by the process in some way. From every type of air, land, sea and space transport, to the processing of fuels that power them. From critical medical devices to making new jeans look, paradoxically, old and worn.

And virtually every industry in between uses abrasive blasting in some form or another.

That simple nineteenth century observation began an industry with almost limitless applications. Here are some of the many diverse ways abrasive blasting is being used today:

> removal of burrs from hypodermic needles (to prevent excess bleeding after giving blood!)

> surface preparation, prior to painting, of oil tankers and cruise liners

> surface finishing of spectacle frames

> shot peening of car, plane and boat engine components

> aircraft paint stripping

> surface preparation, prior to painting, of oil rigs

> removal of semiconductor excess resin

> shot peening of Formula 1 racing car engine components

> removal of residual meat from bones

> cleaning of food processing equipment

> surface finishing of stainless and titanium cell phone casings

> frosted glass windows

> removal of lead paint from bridges

> shape forming of aircraft wings

> sodium bicarbonate removal of dried ink from printing rollers

> extending the life of car, bus and truck coil and leaf springs

> strengthening aircraft jet engine components

> micro smooth finishing of titanium artificial body parts (hips)

> sand removal from iron castings

> building and statue restoration

> burr removal from aluminium die castings

> wooden sign board carving

> headstone engraving

> shaping of denture molds

> removal of paint from log cabins

> removal of rubber from airport runways

> removal of paint from aircraft carriers landing strip

> preparation of concrete car park floors prior to painting

> distressing denim jeans to create a well worn, lived in, appearance

And on and on and on and on…. So you see, it’s everywhere. And I’ll bet you did not even notice.

Welcome to the fascinating world of sand blasting.